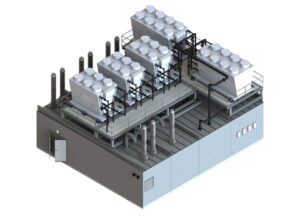

As the chosen manufacturer for the hotel buildings’ central utility plant, we faced two main challenges on this project. First, the hotel was designed to stand alone, “off the grid”, so the prefabricated plant had to provide power to the entire hotel complex; and second, the curved shape of the new hotel building also meant that the plant needed to aesthetically match the curvature of the building.

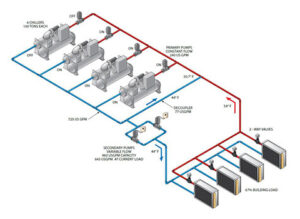

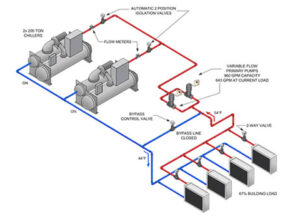

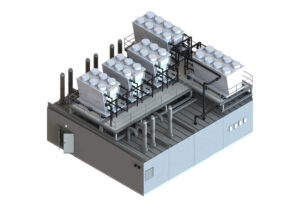

Leveraging the off-site construction(OSC) approach with Epsilon Industries, we worked successfully with Waldron Engineering & Construction, Inc. and Turner Construction Company to design and build a central utility plant that delivers 1 MW of power generation, 1,400 tons of chilled water cooling and 1,200 MBH of hot water heating – helping meet the hotel’s MEP needs for its 512 rooms, conference center, restaurants, and aviation history museum. In addition, each module of the plant was built in a trapezoidal shape instead of a traditional rectangular shape – once assembled on the roof, these modules perfectly matched the curvature of the hotel building.

In the meantime, off-site construction ensured that all units were built and tested in a controlled factory environment, bringing outstanding quality consistency, labor efficiency, cost reduction along with schedule savings and minimized interruption on site. This method allowed us to meet aggressive milestone construction dates and complete the job well within budget.