Properly equipping a LEED-certified laboratory and research facility with energy-efficient HVAC equipment can be quite challenging – especially when the mechanical room to house the systems is extremely small.

To solve this design dilemma, Rockefeller University, general contractor Turner Construction and engineer BR+A New York turned to EJS New York for a custom-designed solution for its Collaborative Research Center (CRC) in New York City.

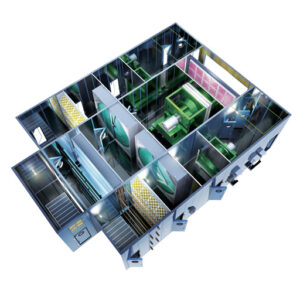

With the assistance of best-in-class design software by Haakon Industries, EJS New York and BR+A designed an HVAC system, including glycol heat-recovery loops to increase the building’s energy efficiency. Specifically, EJS New York provided Haakon Industries Custom Air-Handling Units, created to stack on top of one another to conserve space and proper fan selections to overcome the variable air flow needed to meet the design criteria.

The equipment successfully reclaims energy from laboratory exhaust air and effectively heats and cools the center, which includes a 200-seat lecture hall, café and both 15- and 30-seat conference rooms on each floor of the building.

The result of EJS New York’s design expertise is a state-of-the art heating and cooling system meeting strict LEED qualifications, as well as Rockefeller University’s space and energy requirements.