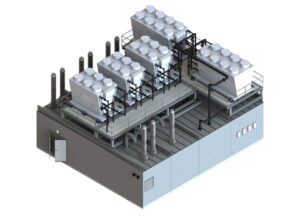

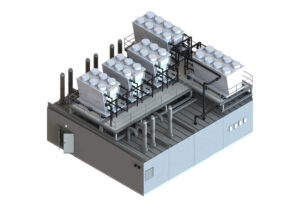

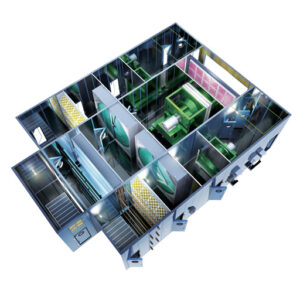

Transforming this site into a full-fledged medical center wasn’t an easy task, but Epsilon and we were up for the challenge and the delivery was massive – a total of 7 packeged cantral utility plants including 1 boiler Plant, 1 electrical Room, one chiller skid, 1 DHW skid, 1 electrical room skid and 2 IDF closets! Utilizing top-tier components, we made sure that the completed systems can meet the hospital’s HVAC needs while providing maximum reliability and durability.

On the other hand, as all the units were assembled back in Epsilon’s factory, this allowed the manufacturing process to go in parallel with other onsite construction, saving big on the project’s overall timeline. The commissioning process was also much simplified thanks to off-site construction, as each unit was directly shipped in modules to the site for a plug and play install.

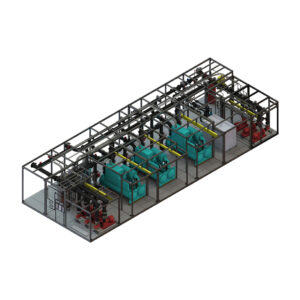

As the building was repurposed from a retail space, its air handling system also need to be repurposed. For this part, we partnered with Haakon and provided 5 custom air handling units. Ranging from 55,000 to 65,000 CFM, these AHUs feature quiet and efficient Q-PAC ECM fan arrays (with N+1 fan redundancy), 2” wall and roof insulation, and air filters up to MERV-14 to meet air handling requirements in a hospital setting.