The main goal of the project was to design a reliable, long lasting, and cost effective HVAC system that meets tight footprint and acoustical requirements while also helping create for the building a “home away from home” feeling that encourages students to commingle in new ways.

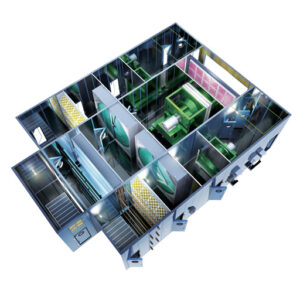

Working closely with AECOM Tishman, Cameron Engineering, Haakon Industries Ltd., Klimor USA Inc. and Nelson Air Device Corp., we provided 4 Haakon rooftop AHUs @ 24,550 total CFM, 1 Haakon DOAS @14,820 CFM with energy recovery wheel and dehumidification heat pipe, 4 Haakon Vertical Indoor AHUs @ 15,310 total CFM and 4 Klimor Indoor AHUs @ 18,945 total CFM. These units are highly customized based on spacial limits and load requirements to perfectly address the building’s air handling needs and acoustical challenges. Together they helped support this sustainable building built around the standards of both LEED Silver and Passive House by using heat recovery features and energy efficient components.

With the design of this HVAC system we hope to bring all students a new sense of belonging with excellent indoor air quality and occupant comfort.